This is still a draft (third version). Come back for the final version, you'll probably be surprised.

--------------------------------

The irony is that when the proverbial S&!# hits the fan, supply chains are disrupted and some people die of starvation, while being surrounded by an abundance of local food sources. Our current economy is very well organized to maximize wealth generation, which means a balance between fulfilling desires and needs of the population, while making money. But at the same time, our economy is unsustainable and fragile. It relies on a web of centralized systems, designed during the industrial era, which are themselves fragile. If one of them fails, the others follow. For example, during the 2008 financial crisis people still needed to eat and farmers still possessed the land and the machines to produce food, but the global food market was greatly disrupted. In capitalism, the market is supposed to readjust to fulfill a new need, but that cannot happen fast enough when the economic infrastructure is affected by a crisis. In socialism, or planned economies, the Government is not well suited to deal with complex situations. Food supply chains can be disrupted because of a regional armed conflict, oil price fluctuations, financial system collapse, bad weather conditions, pandemic, to name just a few, without digressing into nuclear and asteroid collisions. The best way to deal with these situations is a mix of button-up and top-down approaches within a commons-based peer production framework.

|

| Store in Venezuela, country with the largest oil reserves. |

In normal times, entire populations depended on staples produced by the industrial agriculture. These products are designed to concentrate a lot of nutrients and, in normal times, it makes economic sense to consume them. The paradox is that when access to these products is disrupted, people can starve while being surrounded by an abundance of food. Many indigenous eatable plants grow around us but we have forgotten how to prepare them. I live in Canada and the great majority of food products that are available in groceries are not indigenous. In times of crisis we eat what we find. Are we prepared to process local food sources?

|

| Delicious Romanian nettle soup |

Modern technology allows us to more efficiently extract and concentrate nutrients from indigenous plants that are not part of our diet in normal times, as they compete with modern agriculture products.

If one day nettles are the only remaining thing that we can eat we'll need time to learn how to prepare them. To get the equivalent in protein of a steak, one needs to eat a 25Kg stack of nettles. Obviously no one can have that in a single serving. In times of crisis, knowing how to make nettle soup is not enough. We need to learn how to extract and concentrate the protein, and how to cook a delicious meal much like a filly tofu dish. That requires learning time and specialized tools. If it is not in our culture to eat nettles, in normal times it is hard to convince people to learn how to prepare them or to invest in equipment to process them.

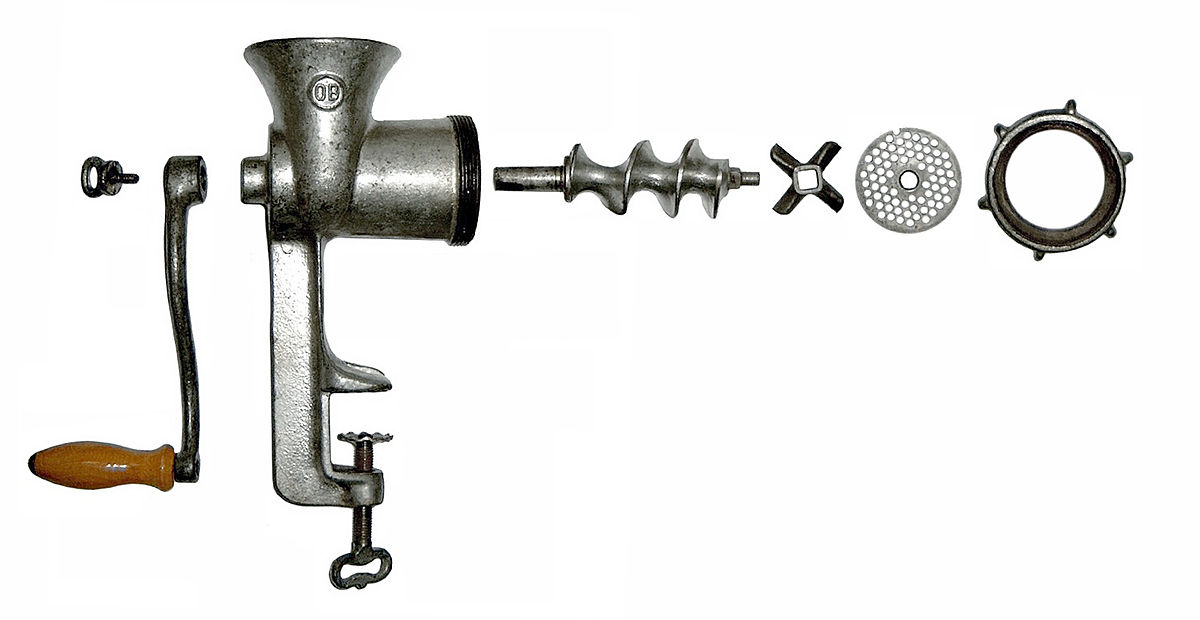

How to tap into the latent food capacity and be always prepared for rough times? The solution proposed by Greens for Good, an open venture nurtures within the Sensorica OVN, is a versatile food processor that in normal times can mill corn, extract oil from seeds, make tofu, make noodles and all sorts of other tings, while also being able to process eatable indigenous plants. On top of guaranteeing food security, this technology also makes food more sustainable by expanding our food sources, and by encouraging consumption of plant-based proteins instead of animal protein. This seams like a very ambitious plan, but we are not in uncharted territory.

In recent years, 3D printing has revolutionized fabrication. A 3D printer is a versatile technology that can come in the form of a desktop machine able to make toys, and can be easily scaled to a larger rig that can build an entire house in a single day. Almost anything that we can imagine, of any shape and practically of any type of material can be 3D printed. Sensoricans' plan for food processing is similar to what what 3D printing has done to fabrication.

3D printing was invented in the 80'. The Fused Deposit Modeling (FDM) patent expired in 2009, and marked the beginning of the 3D revolution, with the open source hardware community swarming this technology. Sensorica's economic model builds on the open source mode of innovation, inheriting the same properties of rapid development and viral dissemination. But it adds an economic layer on top of the innovation model to ensure proper dissemination, cultural appropriation and adoption of the new technology, this increasing its impact.

In September 2022 the network focuses on the prototyping and testing of an open source decanter centrifuge, a critical component of the extruder, responsible for separating fluids and solids according to their density differentiation.

Have an idea about how to improve this post? Please leave comments blow.